Structural Steel and Plate Fabrication

Structural Steel and Plate Fabrication is at the Core of What We Do

For 20-plus years, ITS has been laser-focused on one simple goal: to work in partnership with our clients, primarily industrial and commercial partners, to build long-term, lasting relationships. Across the board, our skilled and experienced designers, engineers, project managers and fabricators are committed to delivering superior, cost-effective solutions designed to help our customers achieve the highest level of success.

As a result, we’ve built a large base of loyal customers that know they can count on ITS for turnkey structural steel and plate fabrication products—from simple orders to highly complex custom projects. Industrial Technology Services (ITS) is a Michigan-based company that specializes in comprehensive structural steel and plate fabrication services.

Within our 20,000-square-foot facility, our workforce utilizes state-of-the-art equipment to process raw materials into workable shapes, AKA, structural steel and plate fabricated products. These products serve a wide range of industries including construction, automotive, energy, infrastructure and much more.

Contact UsFacility Safety Products

Custom Guard Rails

Mezzanines

Structural Fabrication

Plate Fabrication

Custom Ladders & Roof Access

Material Storage Platforms

Hopper Access Platforms & Ladders

Industrial Paint Finishings

AWS D1.1 Certified Welders

MIG, TIG, & Stick Welding

Burning, Bending & CNC Plasma Cutting

What is Structural Steel Fabrication?

ITS has built a solid reputation as a leader in structural steel fabrication, which is the multi-step process we use to cut, shape, bend and assemble raw steel into final building components for a wide range of uses. By employing skilled labor, precise engineering and advanced machinery, ITS produces strong, durable and safe steel structures. Here are the key steps in our process:

Learn MorePlanning

Fabrication begins with the creation of detailed drawings and plans for the steel structure. Taking into account factors such as building codes, load capacity, intended use and weight distribution, designers and engineers use software to design a product and process to meet customer needs.

Cutting/Shaping

The raw steel members are processed using various cutting methods including shearing, plasma cutting or oxy-fuel cutting, which prepares the steel parts for the bending and forming processes.

Finishing

To enhance durability and appearance, fabricated structural steel components may receive surface treatments such as protective coatings or paint.

Material Selection

Structural steel is available in a variety of grades. Based on project specifications, engineers select the option that delivers optimal strength and performance. This is critical because it helps ensure the end product meets or exceeds the customer’s needs.

Bending & Forming

Equipment such as rolling mills, press brakes and/or tube benders transform the steel into desired shapes. This phase is important for developing angled or curved components.

Quality Control

Strict quality control measures are implemented to ensure the fabricated components meet required specifications and standards.

An Expansive Variety of Steel Fabrication Products

ITS serves a wide range of customers across a multitude of industries. As such, we offer a vast array of structural steel products. This includes:

Beams

I-Beams (AKA, H-Beams or Universal Beams): Typically used for supporting heavy loads.

Wide Flange Beams: Provide greater stability and support.

Columns

Square and Rectangular Tubing: Delivers strength with a lightweight structure.

Round Tubing: Used in a variety of structural applications.

Bracing

Bracing systems that help strengthen, fortify and stabilize areas of a structure against certain loads, forces or movements.

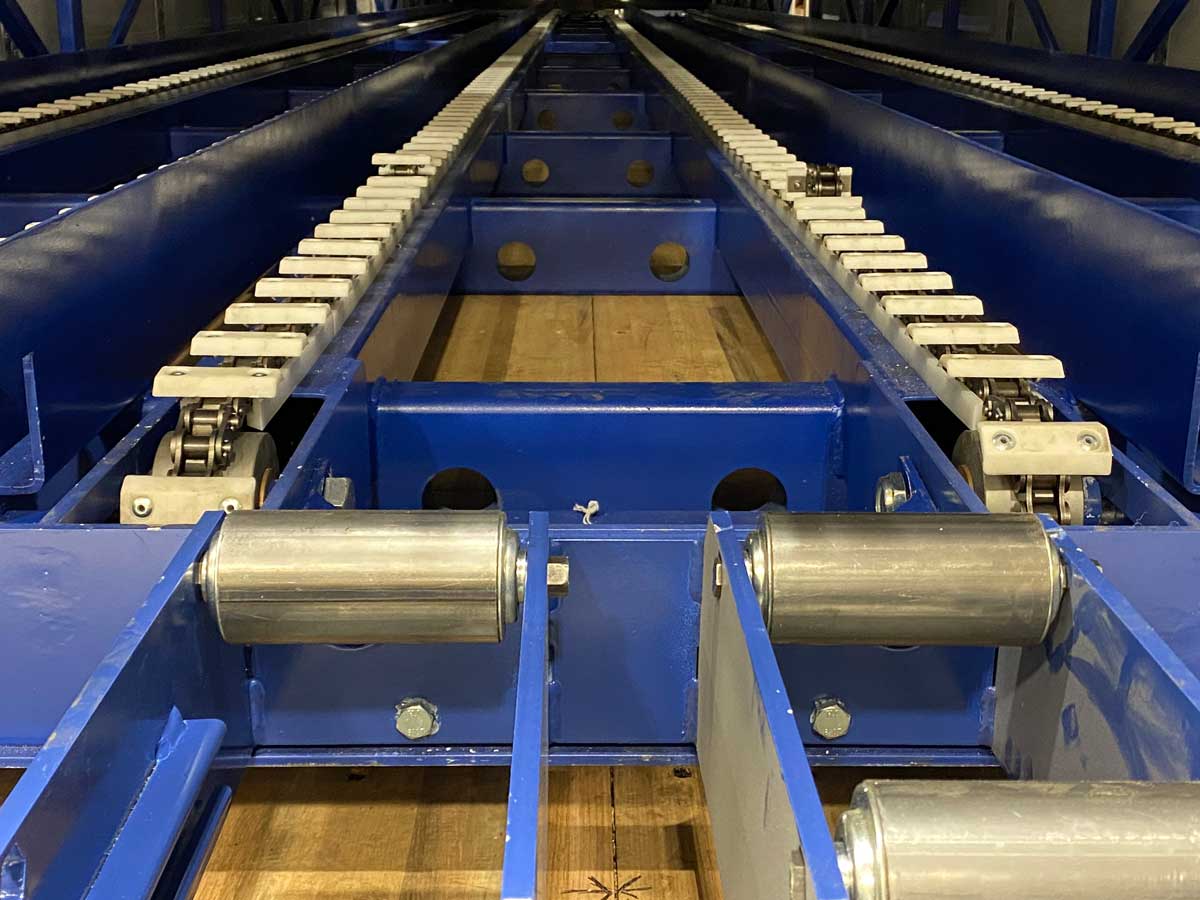

Decking

Roof, floor and composite decking that provides a strong, reliable and versatile base for various building structures.

Structural Steel Fabrication That Serves a Wide Range of Industries

You’ll find ITS structural steel fabrication products in a wide range of industries including, but certainly not limited to, industrial applications. Our offering includes:

Staircases & Elevators

Steel-fabricated staircases, handrails, elevator shafts and support structures.

Structural Support for HVAC & Mechanical Systems

Steel frames and platforms custom-designed to support heavy equipment on the inside, outside or rooftop of a facility.

Custom Fabrications

Tailored to specific architectural and engineering requirements, including custom beams, columns and other structures.

Mezzanines

Steel-framed intermediate floors in warehouses and industrial buildings.

Steel Tanks & Silos

Large-scale storage solutions for commercial and industrial use.

Additional Applications Served With Structural Steel Fabrication

- Commercial

- Automotive Manufacturing

- Aerospace Industry

- Energy Sector

- Military and Defense

- Transportation Systems

- Industrial Equipment

- Sports and Entertainment Facilities

- Government Facilities

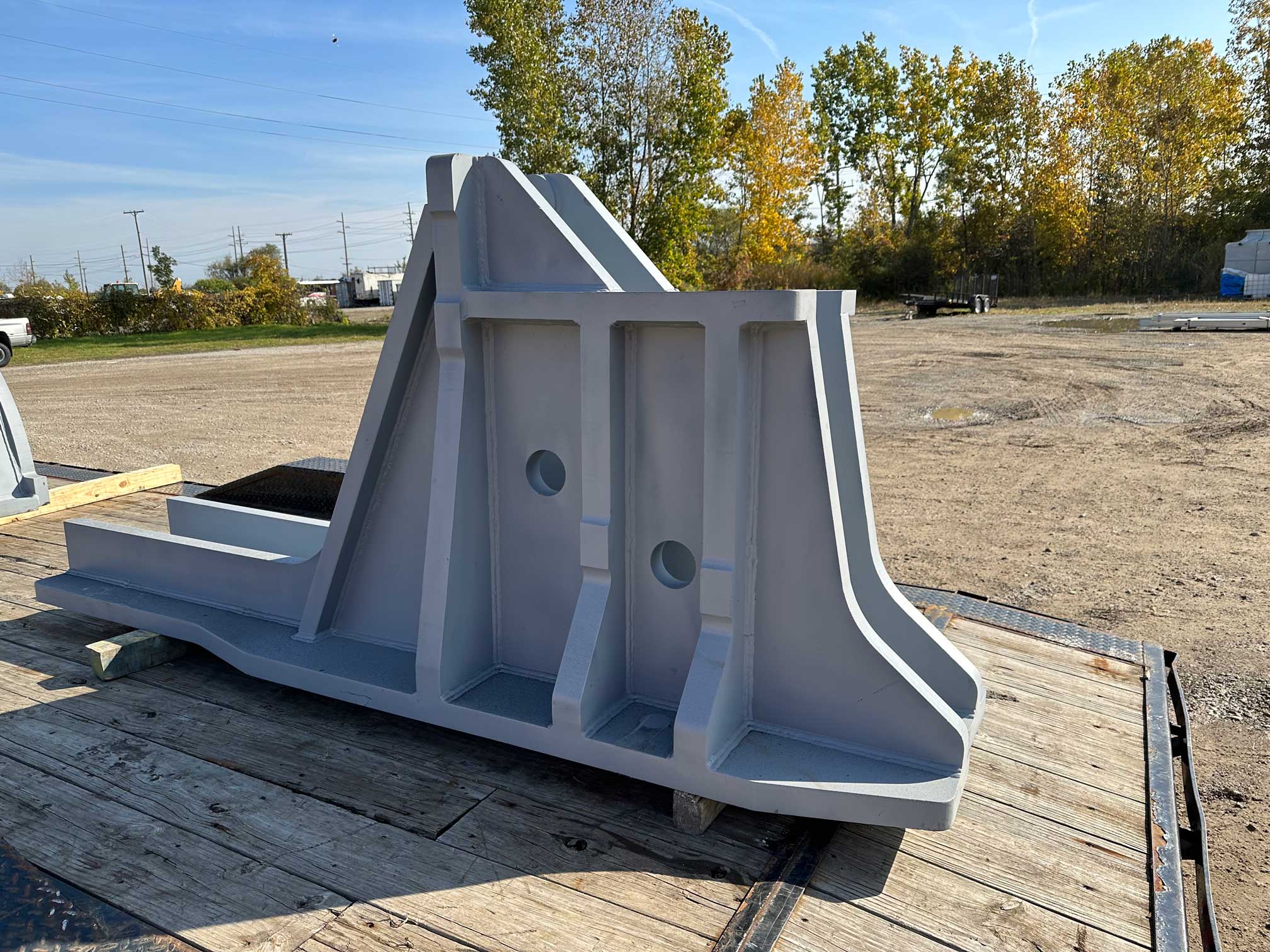

What is Steel Plate Fabrication?

Plate fabrication is another ITS strong suit. This service involves the cutting, forming, welding, assembling and finishing of steel plates into components or structures based on the specific design requirements of our customers.

The importance of this service within our structural steel and plate fabrication offering cannot be overstated, as the steel plates we produce serve as vital structural components of bridges, pillars, columns, storage tanks, pressure vessels and silos, to name just a few.

Our steel plates range from a few millimeters to several inches thick and are used in a vast array of industries including construction, transportation, manufacturing, energy, mining and more. These industries count on ITS for steel plate fabrication of the highest quality—and we deliver by adhering to a tried and true process, which includes:

Learn MoreCutting

Raw steel is prepped and then cut to required dimensions using a variety of cutting methods including plasma cutting, oxy-fuel cutting, laser cutting or waterjet cutting.

Shaping/Forming

This step involves bending steel plates into desired angles and shapes using a press brake machine. If required, steel plates are passed through rollers to create curved or cylindrical shapes.

Welding

To join plates, one of the following welding processes is performed: MIG welding (metal inert gas), TIG Welding (tungsten inert gas) or submerged arc welding.

Assembly

This stage involves putting the cut, shaped and formed steel plates together according to the design specifications.

Finishing

Paint or coating is applied to prevent corrosion and enhance durability and appearance.

Quality Control

Fabricated steel plates and welded joints are inspected for defects, ensuring they meet industry standards.

The Advantages of Structural Steel & Plate Fabrication

It’s hard to imagine a world without structural steel. In its absence, skyscrapers would not exist and buildings would only be two or three stories tall. The same structures would also have difficulty withstanding extreme weather and seismic earth events. Without question, structural steel is a building material unlike any other, offering a number of important advantages. Here are just a few:

Strength-to-Weight Ratio

When it comes to sheer strength, you’ll be hard-pressed to find a material that can outperform steel. Given that structural steel weighs up to a third less than comparable materials, it’s easy to see why it’s such a valuable component of pretty much every building.

Durability

With properties that make them capable of withstanding significant stress, steel plates are known for their high tensile strength and durability. In fact, steel is stronger than most building materials, including concrete. It’s also important to note that as one of the toughest building materials, steel won’t ignite or spread flames.

Versatility and Customization

Structural steel is available in a variety of sizes and thicknesses. This allows for flexibility in design and application, as steel plates can be cut, shaped and welded to fit specific customer requirements.

Cost-effectiveness

Structural steel costs less than other building materials such as aluminum or titanium. Additionally, prefabricated steel components can accelerate construction timelines, which can also lead to cost savings.

How to Choose the Right Structural Steel and Plate Fabrication Partner

Choosing the right structural steel fabricator for your project can be difficult when you consider the extensive range of options available across such a unique and specialized field. With this in mind, it’s important to consider the following factors that will help you consolidate your choices and find the structural steel and plate fabrication partner that can meet your requirements.

Facility Capabilities

The bottom line is this: you need someone who can get the job done right the first time. Whether your project is simple or complex, you want to look for efficiency and quality in the fabrication process, which are usually determined by the technology and equipment utilized. ITS, for example, has made significant investments in cutting edge technology. We are well positioned to provide our customers with exceptional results.

Quality Control Measures

It’s important to ensure that your structural steel and plate fabrication partner holds relevant certifications and follows industry-standard quality control measures. Check to see if a potential partner is committed to delivering a level of quality work that meets or exceeds inspection requirements.

Experience and Expertise

One of the most important factors to consider when selecting a structural steel and plate fabrication partner is experience. Ask yourself these questions: Does the fabricator have experience with projects like yours? Do they serve other clients in your industry? Do they have the expertise and track record to handle a project of your scale? If not, keep looking.

Customer-Centric Approach

Here’s another important question to ask when evaluating structural steel fabrication partners: Does the fabricator take the time to really understand your business and your unique fabrication needs? You’ll know the answer within 15 minutes of your first encounter. Keep in mind that much more than a relationship, you’re looking for a partnership.

Choosing the right structural steel and plate fabrication partner is vitally important. It will go a long way in helping you avoid setbacks in your project timeline while preventing budget overruns.

Let’s Start a Conversation About Your Next Structural Steel Project!

To learn more about Industrial Technology Services and our commitment to provide your business with the very best structural steel and plate fabrication services, give us a call at (586) 330-9031.