Precision Plate Fabrication for Heavy Industrial Application

For industrial projects to be successful, precision metal plate fabrication is essential. Metal plates are cut, shaped, and assembled to produce parts that are vital for machinery and equipment used in a variety of industries.

At ITS, we take great satisfaction in our in-house capabilities and our extensive experience in heavy-duty steel and plate fabrication. From cutting and shaping to welding and finishing, ITS handles the full lifecycle of your plate fabrication under one roof. With decades of experience and our 20,000-square-foot facility, our workforce serves key industries across the United States.

Contact Us

Full-Service Metal Plate Fabrication

For heavy-duty industrial applications, ITS provides a wide range of metal plate fabrication services. Whether you’re manufacturing precision assembly, installing huge equipment, or strengthening buildings, our team works with carbon, stainless steel, and specialty alloys to create everything from machine baseplates and mounting assemblies to meet your specific requirements.

Cutting

Depending on the thickness, material, and tolerance requirements, our fabricators shape steel plates using a variety of cutting techniques.

- Water jet cutting: No heat-affected zones, ideal for delicate or composite materials

- Plasma cutting: Ideal for medium-to-thick steel plates

- Oxy-fuel cutting: Best for very thick plates and rough cuts

- Laser cutting: High-precision cutting and clean edges for tight tolerances

Welding

When joining plates, our certified welders guarantee strong, clean welds using processes such as:

- MIG welding: Great for thicker materials and speed

- TIG welding: Ideal for thinner metals or stainless steel and precision work

- Submerged arc welding: High-quality welds for thick, heavy plates

Finishing

Once fabrication is complete, we apply paints or coatings to protect against corrosion, enhancing durability and appearance.

Drilling

ITS uses different methods to drill holes or slots into steel plates with accuracy and repeatability.

- CNC drilling equipment for automated, recurring designs

- Magnetic Drills or mag drills for on-location, precise drilling

- Drill presses for consistent depth and alignment

- Manual or hand drills for short-term, small-volume work

- Multi-spindle machines for fast, multi-hole drilling operations

Shaping/Forming

To produce components with specific angles and shapes, ITS uses advanced press brake machines to bend steel plates accurately. In cases requiring curvature, we pass plates through rollers to achieve curved or cylindrical shapes.

Quality Control

AT ITS, quality is paramount. We rigorously inspect steel plates and welded joints, ensuring that every component meets the highest standards before it leaves our facility.

An Expansive Variety of Steel Fabrication Products

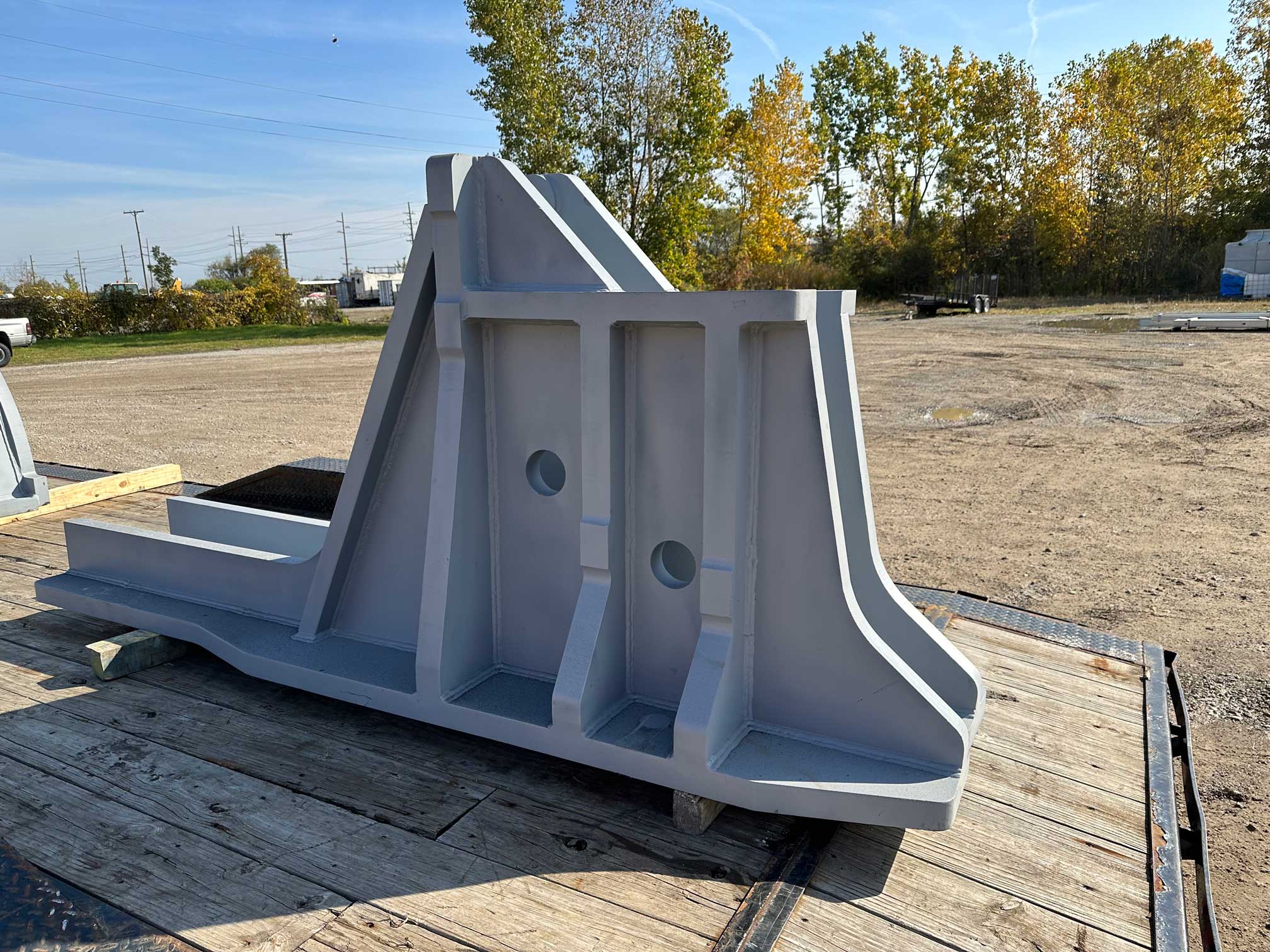

ITS specializes in equipment plating, reinforcing, and supporting industrial machinery with heavy steel plate bases. For heavy-duty machinery, we design and fabricate baseplates that provide stability, load distribution, and vibration reduction. Our plates are used in conveyor systems, motor bases, mounting skid frames, and other structural assemblies.

Custom Plate Fabrication for Structural and Mechanical Needs

We provide turnkey solutions tailored to your specific requirements. From unique cutouts and multi-axis hole patterns to tailored thickness and plate length, we fabricate to exact specs. Our plates are designed to integrate seamlessly with your framing systems, supports, and process equipment.

Equipment Mounting and Structural Support Solutions

Plate fabrication often works hand-in-hand with equipment mounting. ITS offers precision-fabricated plates that serve as interface layers between structural systems and heavy machinery, support brackets, and machine foundations. We develop baseplates that are bolted or welded to guarantee that the machinery sits securely and level. Turnkey installation and reinforcement are made possible by the integration of our manufactured plates into platforms, skids, mezzanines, and support steel.

Industries Served

Automotive & EV Manufacturing

In the automotive and EV industry, our fabricated plates are used for mounting robotic arms, aligning machinery, and reinforcing chassis assembly systems. Under heavy production tools, reinforced steel bases provide precise machine alignment and long-term durability.

Packaging & Food Processing

Packaging lines, conveyors, and mixers are all mounted on our sanitary-grade stainless steel plates. These plates provide structural stability beneath heavy or vibrating machinery, preventing corrosion and allowing for easy cleaning.

Heavy Manufacturing

Facilities operating heavy presses, furnaces, or mills rely on our thick steel plates to provide structural support. Our plates are also integrated into walkways, platforms, and access platforms to improve safety and reduce vibration during operations.

Plastics & Injection Molding

To better stabilize the machine body and reduce flex, ITS offers strengthened plates underneath extruders and injection molding machines. For dependable tooling support and mold alignment, we also manufacture mold support plates with high precision tolerances.

Power Generation

From generator skids to control panel platforms, our plate fabrication supports power generation and transmission equipment. These steel plates offer the stability needed to handle vibration and environmental stress in a demanding utility environment.

Aerospace & Defense

For aerospace and defense, we provide vibration-isolated baseplates and component testing platforms, which require a high level of accuracy and toughness durability. Our plate fabrication services meet the exacting standards of mission-critical applications.

Why Choose ITS for Metal Plate Fabrication?

Using our 20,000-square-foot facility, our fabricators are given access to heavy-duty tools and machinery that allow us to work with thick steel plates and oversized materials in-house.

In-House Fabrication Shop with Heavy-Duty Tooling

Using our 20,000-square-foot facility, our fabricators are given access to heavy-duty tools and machinery that allow us to work with thick steel plates and oversized materials in-house.

Industry Certified Welders and Fabricators

Our team includes certified welders, machinists, and fabricators who are committed to delivering precision and quality every time.

Fast Lead Times & Consistent Quality

We work quickly to minimize your business’s downtime and have rigorous quality assurance practices to guarantee you get the same quality of service whenever you work with us.

Turnkey Support from Design to Installation

ITS provides turnkey solutions tailored to your sector’s specific needs, ensuring optimal support throughout design, fabrication, and installation.

Ready to Build with Strength?

Contact ITS today to talk about your next plate fabrication project. Whether you need standalone baseplates or a fully integrated system, we deliver steel solutions that last.