Automation Control Systems

Complex Automation Control Systems for Simple Industrial Solutions

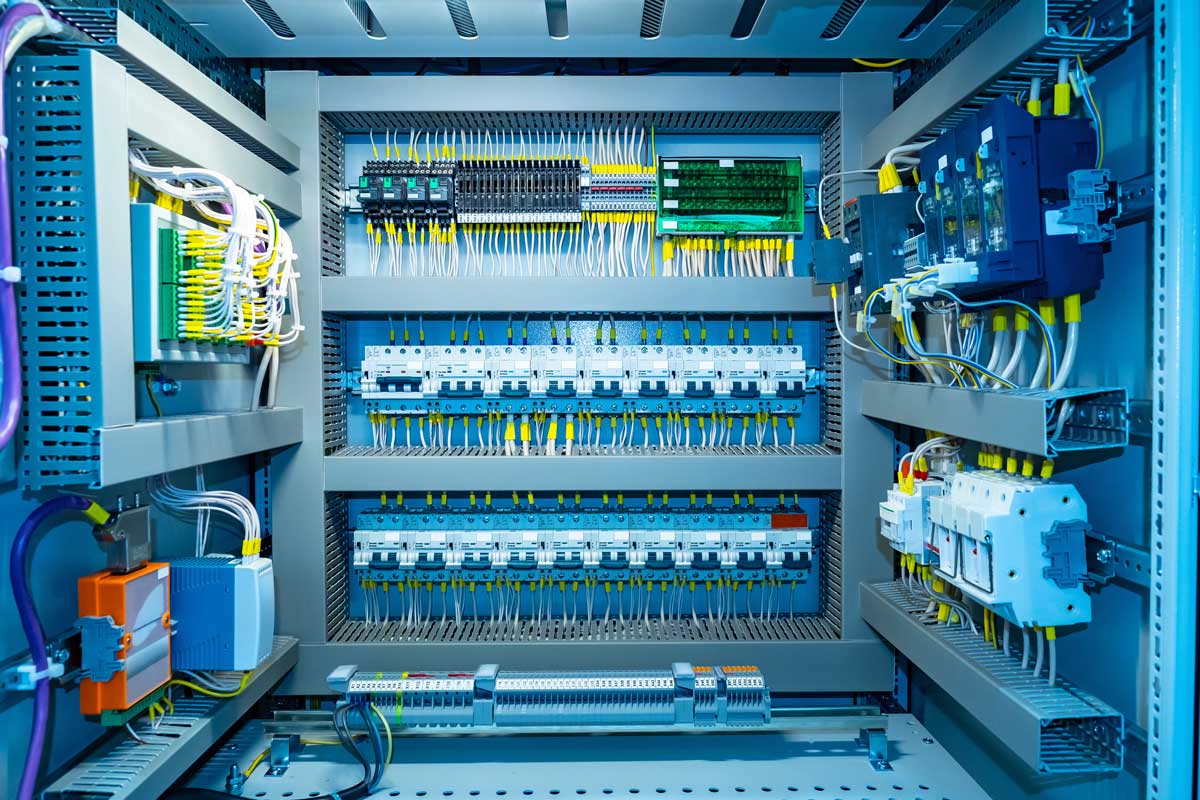

Industrial Technology Services (ITS) understands that quality automation and control systems will result in improved productivity. With this in mind, we design, build and implement customized control systems in industrial and manufacturing environments.

Our engineers provide an a la carte approach to servicing customers. We can deliver perfectly tailored automation and control solutions to meet your individual needs, from project consulting through full-scale design and implementation. Our systems maintain control of variables like temperature, speed, and pressure, ensuring that every process meets our superior standards of consistency and craftsmanship.

Contact UsUnderstanding Your Control Systems

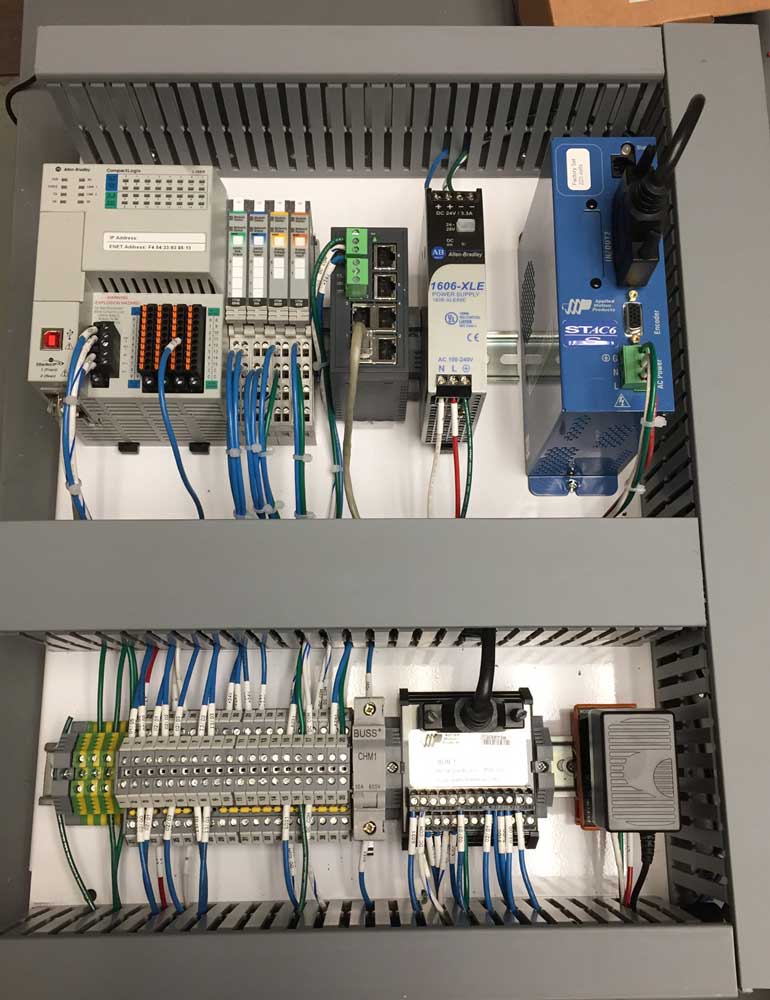

A control system is the backbone of automation and your key to staying competitive. ITS provides a full suite of automation control services, each designed to support the operational and production needs of our clients. We offer open-loop systems and closed-loop systems to help you better streamline complex processes for all industries. Both systems play distinct roles:

Open-Loop Control Systems

Open-loop control systems perform tasks based on pre-set instructions and do not adapt to changes in output or environmental variables. ITS’s open-loop solutions include:

- Conveyor Belt Systems: A system where constant operation is needed without any adjustments. We provide configurations for conveyor belt operations to keep consistent speed for material transport.

- Basic Motor Control Systems: For automation that requires simple and repetitive actions, like pumps or basic machinery operations, ITS provides efficient open-loop solutions.

- Custom Open Loop Configurations: ITS works with our clients to design and build open-loop solutions tailored to your specific production requirements

Closed-Loop Feedback Systems

Closed-loop systems operate with sensors and feedback mechanisms to actively monitor and adjust outputs, allowing real-time control of any changes to the environment or system state to maintain optimal performance within parameters. These systems alert operators to failures and past successes. ITS’s closed-loop services include:

- Automated Flow and Pressure Controls: ITS designs flow and pressure control systems with feedback loops to maintain consistent fluid airflow, which is crucial in chemical processing and wastewater management.

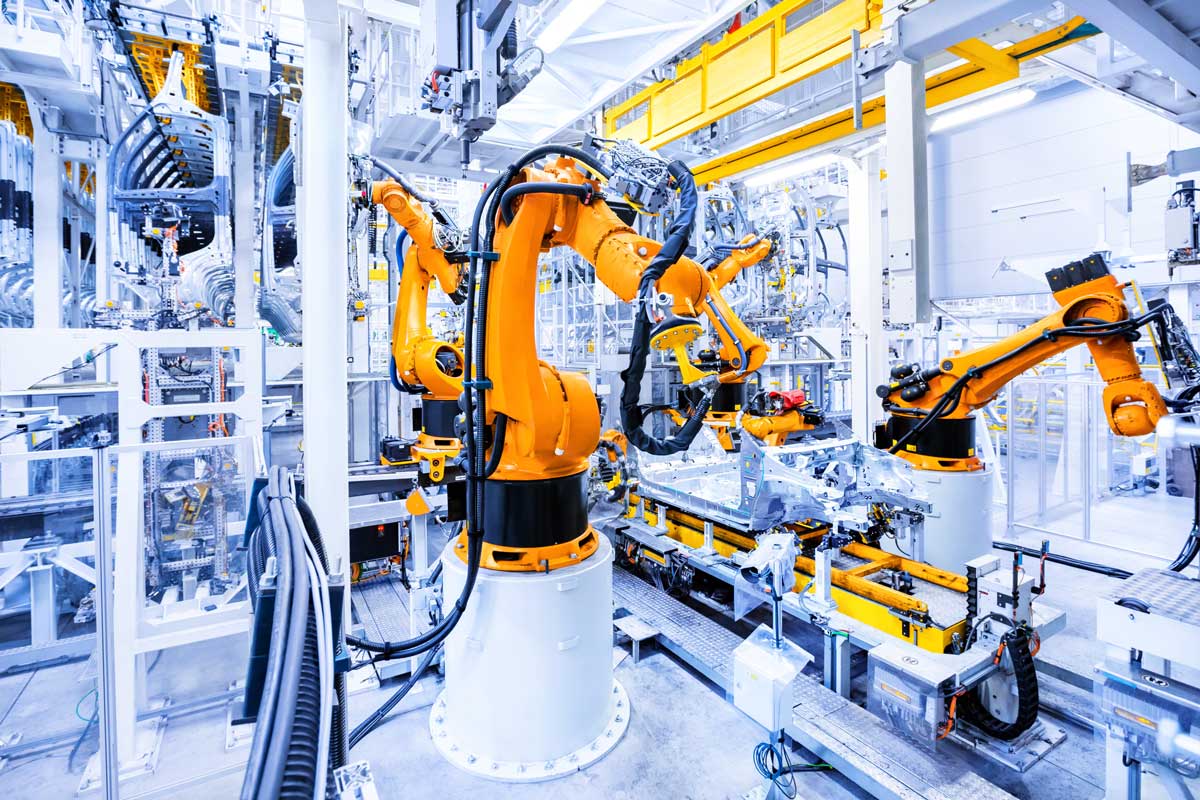

- Positioning and Servo Control Systems: Our engineers provide applications for exact positioning, such as robotics and CNC machinery, guaranteeing highly accurate and repeatable processes.

Seamless Integration and Automation

Successful automation depends on well-integrated systems that allow equipment and systems to work together. ITS’s integration services guarantee that every component interacts efficiently, giving real-time data that allows automatic decision-making and modifications.

Our expertise includes full automation deployment, allowing operations to run with minimal human interaction, lowering human error and increasing the efficiency of your product line.

Tailored Application Engineering for Your Industry-Specific Needs

ITS creates custom solutions that align with our clients’ specific industry requirements. Our engineering team wants to understand each of our client’s operational needs and develop application strategies that maximize the performance of their systems. Working with us isn’t just about meeting your specifications; we want to exceed them and optimize system performance. This includes:

- Custom Configuration: Our engineers tailor control strategies that match client requirements.

- Optimization: We improve performance metrics like throughput and safety compliance.

- Training and Support: We offer on-site training for smooth system operation and troubleshooting.

Machine Integration for Cohesive Workflows

Existing and New Equipment Integration

We believe effective machine integration is vital for creating seamless workflows. At ITS, our machine integration services allow us to incorporate different types of equipment, whether new or legacy, and allow your machines to communicate and operate in tandem, improving production flow, reducing redundancies, and enhancing overall performance.

Improving Productivity Through Machine Integration

ITS’s machine integration solutions supply real-time data shared across machines, allowing operators to monitor performance, solve problems instantly, and make rapid modifications. This degree of integration increases productivity while retaining optimal performance.

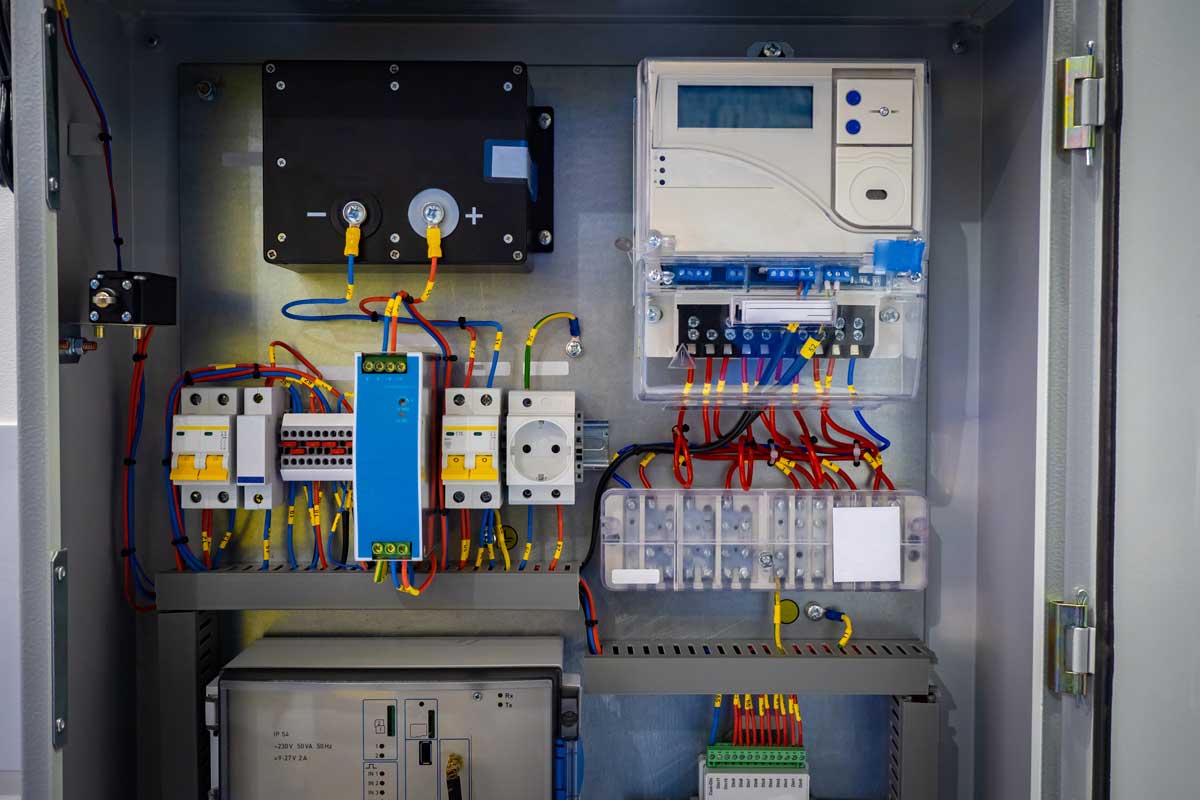

CAD Services

Our CAD Services Include:

Detailed Design and Prototyping

We provide design services, including creating detailed drawings, wiring diagrams and system layouts. Through virtual prototyping, our team will help you visualize the end product and make necessary adjustments to ensure everything is accurately represented before physical production.

Customization and Flexibility

Every industrial operation is unique, and our CAD services reflect that. Our engineers work closely with you to customize designs to meet your specific operational needs, allowing any input and rapid adjustments as your project evolves.

Collaboration and Documentation

We collaborate with our client’s engineering teams, communicating in real-time and sharing designs and modifications. This hands-on approach ensures all major stakeholders are aligned and contribute to the design process.

Custom Machine Design for Specialized Needs

ITS specializes in custom machine design to address each client’s unique production challenges. We’re ready to create tailored solutions for our clients, everything from simple parts to complex machinery and automated production cells. Our engineers work closely with our clients to develop anything for your needs.

Examples of IT’S Custom Machine Design Capabilities:

- Custom Widgets and Small Components: We design and build small, specialized components to support larger production needs.

- Automated Welding Machines: ITS can create machines specifically designed for welding application, increasing consistency and efficiency while reducing labor costs.

- Assembly Line and Automation Cells: From simple assembly lines to complex cells, ITS creates systems that integrate multiple functions, allowing for continuous, smooth production.

ITS’s custom machine design is part of our ala carte method to deliver innovative, tailored solutions that enhance our clients’ capabilities that fit into your existing processes. With a focus on scalability and reliability, our custom-made machinery guarantees your operation can adapt and grow as needed.

Why Choose ITS for Your Automation Control Needs?

Ensuring Success at Every Stage of the Project

ITS’s automation project’s process is structured to guarantee success. We begin every projection with an in-depth consultation to understand your needs. Each step, from design to installation and maintenance, is carefully planned and executed.

Our Process Includes:

- Consultation Need and Assessment: Collaborate with controllers, facility managers, and major stakeholders to define project goals and requirements.

- Custom Design and Engineering: Develop tailored designs and engineering solutions.

- Installation and Integration: Install systems with minimal disruption to operations

- Ongoing Support and Maintenance: Provide continuous support to ensure your project is operating at optimal performance.

Ready to Automate Your Operations? Contact ITS Today!

ITS is ready to partner with you to deliver custom automation and control solutions tailored to your industry requirements. Contact us today to see how ITS can transform your operations with our precision-driven, innovative automation solutions.